Climate Change: Amazing Solutions Created by UC Chile Students

Committed to helping solve the difficult environmental scenario the planet is facing, different students are ready to contribute their creativity and talent to face climate challenges through innovative initiatives. Two incredible projects are ClassiFyber and Durvill.

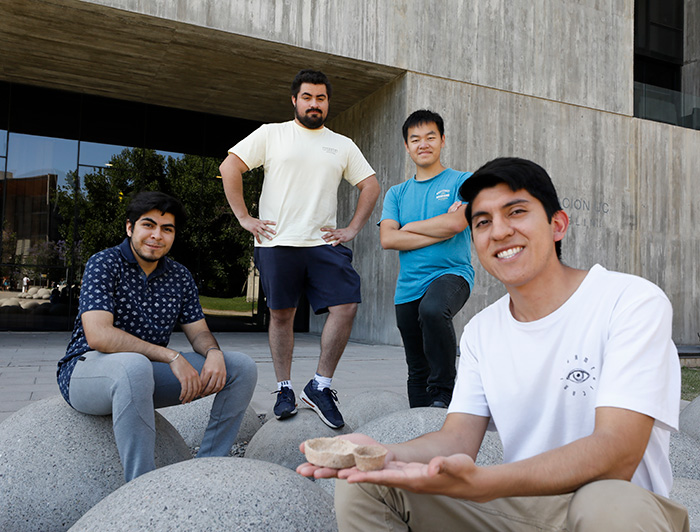

photo_camera The group formed by engineering students and inventors of ClassiFyber, technology that alows to know the composition of fabrics, won first place in the Jump Chile 2022 competition. (Photo by: Jump Chile)

ClassiFyber: Classify Fabrics in 10 Seconds

Every year, around 110 million tons of clothes are thrown away in different parts of the world, waste that is not recycled in any way.

It is a rather alarming situation if we also take into account that 73% of this textile waste is burned and turned into carbon dioxide or monoxide that is released into the atmosphere. The rest pollutes the landscapes of cities and even deserts, as has been seen in northern Chile.

This troubling situation motivated a group of students from the UC Chile School of Engineering to come up with a possible solution.

Following a three-month process of analysis, testing, iterations and improvements, ClassiFyber was born.

It is a device that uses a laser that burns two millimeters of the fabric of a garment and can detect what it is made of by odor. Once its composition is known, it is possible to classify the fabric instantly and automatically.

Knowing what a garment is made of is essential to improve clothing recycling rates, but accuracy is also key. Until now, current technology has only offered spectrometry (a chemical analysis to identify what something is made of), which is slightly more than 70% accurate and costs between 4,000 and 10,000 USD.

In fact, there is only one factory in Sweden that uses this technique.

With the technology developed by UC Chile students, it is possible to know in ten seconds whether the garment is made of polyester, cotton, viscose, or another component, and it is much cheaper than other methods.

According to Maxilimano Mariné, one of the student inventors, this technology:

- achieves 90% accuracy; and

- is much cheaper than today's technology.

They evaluated different algorithms and used machine learning technologies, and conducted several tests in the yard of their home to find this solution.

Afterward, the company Ecocitex provided them with about 30 kg of clothing to have access to a realistic base for testing.

“The beauty of the device is that by separating garments automatically and without people getting in the way, it allows companies in the industry to sort the clothes and market them at a price that can be up to four times higher than today's prices. Currently, they sell it for scraps or for filling,” said Mariné.

The innovative solution could also facilitate the entry of new players who are interested in achieving a higher profit into the business, thus extending the use of the technology to other countries.

The creators are Maximiliano Mariné, Martín Montes, Vicente Lyon, Matías Ovalle, and Martín Bertin. Although they are all engineering students, each one contributed from his specialty and knowledge in the industrial, mechanical, and structural fields, Mariné noted.

The group won first place in the Jump Chile 2022 competition, promoted by the UC Chile Anacleto Angelini Innovation Center and Banco Santander, and was awarded ten million Chilean pesos.

They also won the internationalization program, The Bridge at the UC School of Engineering. As a result, they will soon travel to Boston to meet with experts who can help them perfect their technology and make it available on the market.

Coincidentally, the state of Massachusetts is one of the most advanced in textiles. According to Mariné, the next step of the project is to attach the device to a conveyor belt, on which the garments will pass in an orderly fashion. After being analyzed, the clothing can be selected by robotic arms and pushed into sorting baskets that facilitate the automatic recycling process.

At the same time, the students are working on patent applications and perfecting the technology to increase the precision level.

The continuous improvement and feedback provided by experts and especially by Professor Alfonso Cruz, who teaches the Innovation and Entrepreneurship course, has been key in the whole process. He was the one who challenged them to create sustainable manufacturing.

“We have a natural inclination towards generating a solution and seeing how it can be applied to some problem, and it should be the other way around. We first need to understand the challenge and complexities and then come up with an answer," explained Mariné.

He added that he and his teammates feel a strong commitment to environmental issues.

“The climate challenge is huge and COP27 made it clear that it is a serious situation. So, reducing the amount of clothes that are thrown away and burned can have a major impact."

Durvill: Algae That Replace Plastics

At his family's Chinese restaurant in Santiago, engineering student Zilong Lu found that the food packaging was difficult to work with. Sealing containers with hot liquids was particularly difficult. To avoid spills, a large amount of plastic wrap has to be used to keep it from leaking.

It was this simple observation that triggered the birth of Durvill, a biomaterial made from seaweed that makes it possible to produce packaging that replaces single-use plastics.

The creators are three UC Chile engineering students—Zilong Lu, Matías Cid and Carlos Álvarez—and Alexander Kress, an engineering student majoring in biotechnology at Universidad Andrés Bello.

It is estimated that more than 80% of marine litter comes from packaging and plastic bags.

Chile contributes a good amount: it ranks 11th in individual plastic use worldwide. According to the study “The Plastic Waste Makers Index” (2019) Chile has the highest amount of single-use plastics per person in Latin America, reaching 48 individual kilos per year.

Therefore, this solution would represent a significant step forward.

According to Matías Cid, the material created has a number of favorable qualities:

- it permits the storage of hot food,

- it is biodegradable, and

- unlike other materials, no water is required for its production.

"They are the most sustainable packages on the market," noted Cid.

The solution was devised in March of this year in the context of Professor Francisco Pizarro's Innovation and Entrepreneurship course.

The group of students jumped at the challenge. While they were reviewing the literature, they discovered that algae had good thermal resistance properties.

They began testing cochayuyo, an edible Chilean seaweed. But later they realized that there were other algae that were more economical, such as huiro and pelillo, since they were not edible. These algae also grow very fast in the sea and are more environmentally friendly.

One of the advantages of this biomaterial, according to Matías Cid, is that it could be produced in any country with marine access.

The innovation won first place and a prize of sixteen million Chilean pesos in the Brain Chile contest. The competition is organized by the UC Anacleto Angelini Innovation Center, Banco Santander, and the School of Engineering.

According to Cid, they are evaluating the possibility of reaching an agreement with laboratories and continuing to carry out more tests to produce the biomaterial, make it more flexible and firmer, and achieve a neutral odor.

Additionally, they want to evaluate the option of manufacturing the containers from the algae waste discarded by other companies in the market. They have already been evaluating this option with the company Gelymar, which extracts raw materials for the food and beauty sectors from Chilean algae.

This possibility would also promote recycling within these types of companies.