Chilean Researchers Modelled a Bacterium to Produce Bioplastics

The species Halomonas camaniensis is capable of surviving in highly saline environments. This trait makes it ideal for producing biomaterials such as food containers, cups or bags that do not harm nature as they degrade.

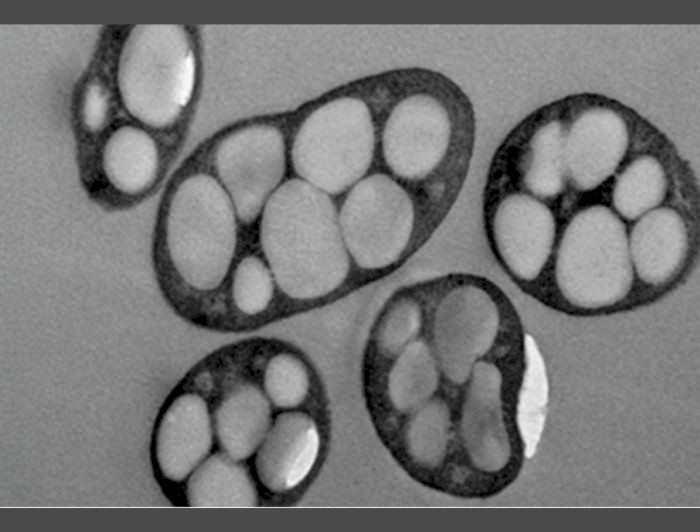

photo_camera Picture of Halomonas campaniensis, a salt-tolerant bacterium species for a healthier planet.

A research team at UC Chile made a huge step toward the development of sustainable solutions to plastic pollution: it is HaloGEM, a computational tool that makes it possible to model bacteria capable of producing precursors for biomaterials.

According to the work published in the new science and technology communication portal ING Divulga from the UC Chile School of Engineering, such innovation not only saves time and resources in lab testing, but also allows for the design of better strategies for producing environmentally-friendly materials.

“The subject of this research is the bacterium Halomonas campaniensis, a species that can survive in highly saline environments. This trait makes it ideal for producing biomaterials such as food containers, cups or bags that do not harm nature as they degrade,” reports Camila Orellana, professor of Chemical Engineering and Bioprocesses and one of the researchers behind this breakthrough.

Professor Orellana added that, through HaloGEm, they were able to computationally simulate how this bacterium feeds, grows, and produces a type of bioplastic precursor called PHB. This material, she said, degrades naturally and is considered one of the most promising alternatives to end the accumulation of conventional plastics. “For example, in medicine, these bacteria make it possible to develop threads used for surgical sutures, which later dissolve on their own inside the body. This is even being tested in cars, plant pots, and agricultural products that help protect the soil,” she specified.

For researcher Pedro Saa, meanwhile, the computational model made it possible to explore how the limitation of certain nutrients affects the production of bioplastics by the bacterium. He also revealed that this tool helped to virtually evaluate its internal functioning to make it more efficient, a process that would take years without this technology.

“The use of computational models such as HaloGEM is key in moving toward a more efficient and sustainable bioindustry. It allows us to anticipate results and optimize processes without relying exclusively on trial and error,” the professor of Engineering from UC Chile stated.